Connecting purpose and technology

Link the purpose of the new IT system and increase the implementation strength towards the goal What if technology could actually do a relatively large part of the…

Link the purpose of the new IT system and increase the implementation strength towards the goal What if technology could actually do a relatively large part of the…

Becker Industrial Coatings AB, one of Sweden’s oldest paint brands, has taken major steps towards sustainability and energy efficiency through collaboration with SenseNode. By combining technology and awareness, Beckers has not only optimized its energy usage patterns, but also set the bar for a greener future.

Facing challenges with increasing costs and a lack of control over energy use, the IS Plåt turned to SenseNode’s energy management system. This decision allowed them to efficiently…

The Energy efficiency directive (EED) was first adopted in 2012, setting the rules and obligations for achieving the EU’s ambitious energy efficiency targets. The revised directive was published in the EU Official Journal and entered into force on 10 October 2023, impacting corporate energy audits and energy management systems (addressed in Article 11 of the directive).

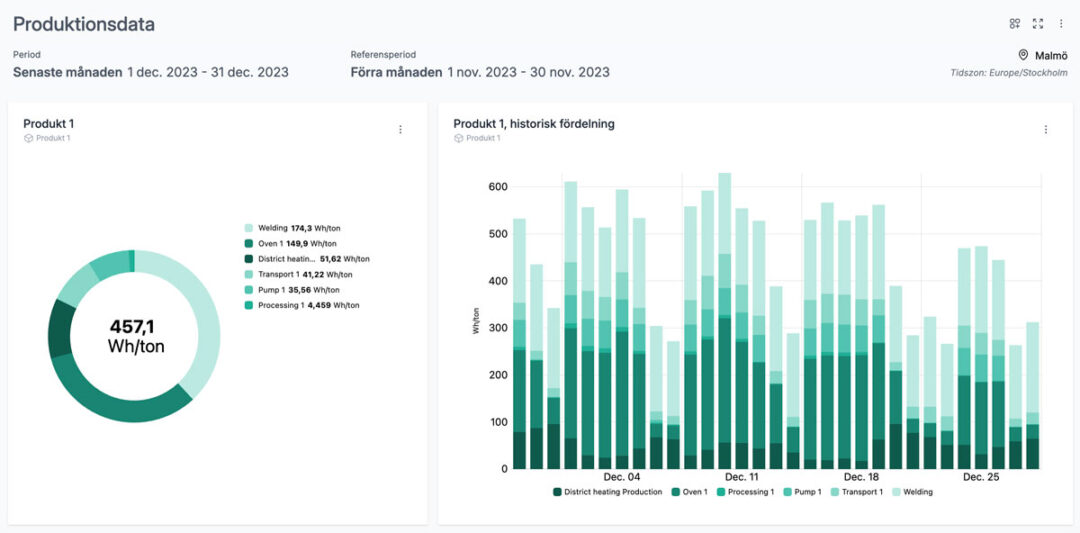

By analysing energy and production data together, production managers can not only achieve improved energy efficiency, but also optimize their production processes. SenseNodes new feature enable integration of…

It seems like the economy might start to ease in the second half of 2024.Something many are looking forward to, production picking up again after the uncertainty and…

Approximately 80 % of the manufacturing Industries have higher electricity distribution and transmission costs than needed. In some EU countries that can be a very expensive mistake.

In 2019, BUFAB Lann AB implemented the SenseNode solution. At that time, they were already working towards making their operations more energy-efficient and monitoring their energy consumption but lacked the necessary measurement tools.

Baosteel needed to review how to increase its energy efficiency and reduce the energy consumption per produced unit.

Effective monitoring and management of power consumption is crucial for optimizing energy efficiency and reducing costs. By accurately tracking power usage from the grid provider in real-time, businesses…

ISO 50001 establishes the requirements for energy measurement to assist businesses in taking control of their energy consumption. In the manufacturing industry, an increasing number of companies are…

Boliden Bergsöe, operating in a challenging environment where molten lead is pumped, faced frequent equipment wear, resulting in approximately 60 pump repairs annually, entailing substantial expenses.